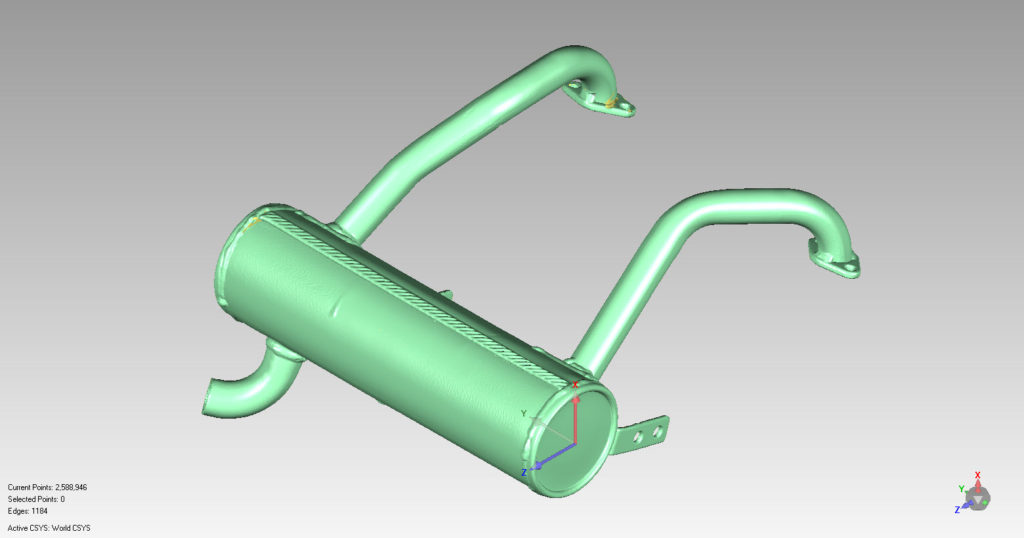

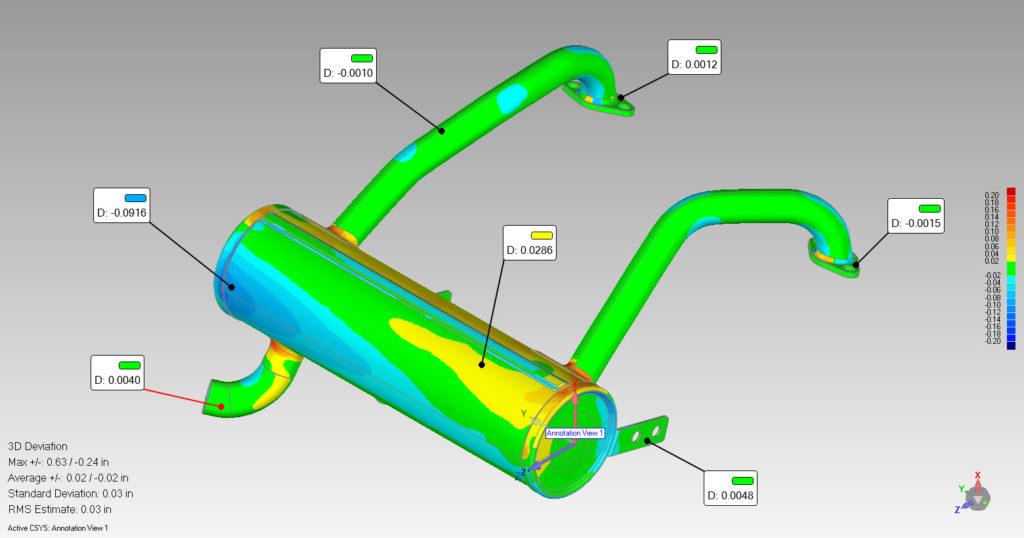

A working prototype muffler for a small maintenance vehicle needed CAD documentation for the creation of an FEA model. The model would be utilized for an FEA (Finite Element Analysis) study as well as a reference model used to request bids from multiple vendors to manufacture the muffler. Veritas scanned the muffler with a FARO Edge portable CMM equipped with a new FARO HD LLP. The muffler was scanned while mounted to the vehicle not only to constrain the muffle but to allow the capturing of surrounding data for an envelope study.

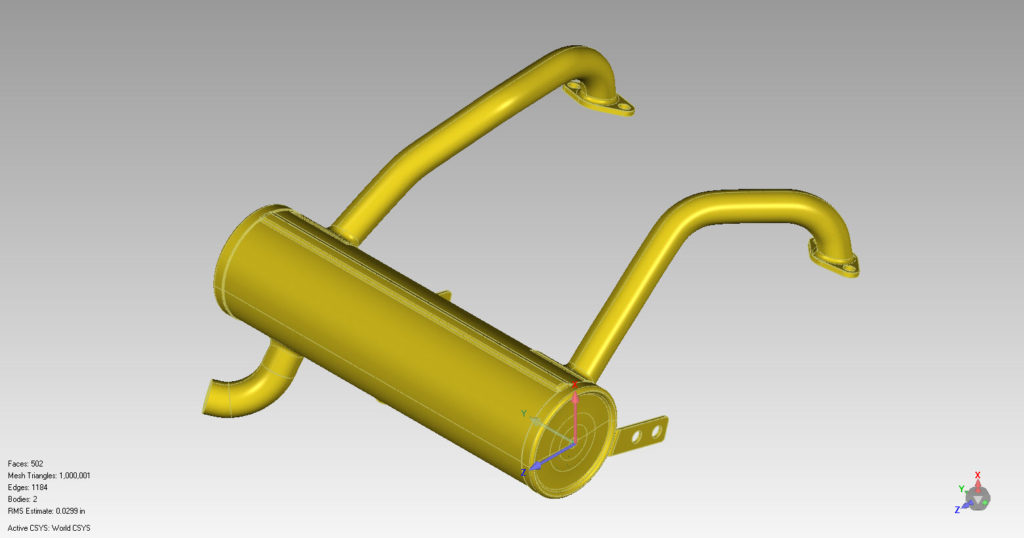

The FEA model was created in Geomagic Design X. In the process of reverse engineering from the scan data we can incorporate “design intent” into our workflow. Design intent modeling allows for deviation from the original scan data while preserving aspects of the part’s design to not only constraining the model properly but make it easier to request changes during manufacturing. Models can be exported from Design X with a feature tree into a native file for your CAD software. If you have a need for documentation of a prototype part please contact us for a quote.